Digital Thread Inspection

Part of the Tubular Solutions culture includes never resting on our accomplishments. We are constantly seeking to improve all that we do. Which is how we developed a new technology, Digital Thread Inspection, that will be a game-changer in the industry.

The Future of Thread Inspection Has Arrived

Tubular Solutions has been a leader in performing visual thread inspections for years. We employ the finest, best-trained people in the industry, and our track-record for accuracy and reliability is unmatched. TSI is committed to continual improvement and has developed technologies that will make thread inspection – as well as laser tally, ID caliper services and tubular inventory management – more accurate and convenient than ever.

Virtually eliminate human error

Our track record – zero failures after 100 million feet of pipe – is a testament to our experience, attention to detail and transparency. But digital thread inspection (DTI) does offer some significant advantages

One tool, many uses

The new digital thread inspection (DTI) tool from Tubular Solutions is the one stop answer for all of your pipe inspection needs.

The ability to share a single digital record allows for client or third-party review from virtually anywhere without the need to be onsite and eliminates the need for separate tools for tally or ID caliper verifications. DTI combines digital imaging, laser measurement, and artificial intelligence software to capture a full digital record of the state of the hardware and identify potential problems in real time. This allows for a highly accurate and repeatable system that you can count on for anything from a single connector to an entire pipe yard.

Accurate and repeatable inspection

The Tubular Solutions DTI system takes the guesswork out of inspecting and accepting hardware. Use of an integrated high intensity LED light source ensures optimal conditions for digital image capture regardless of environment. The high repeatability of the DTI system allows for easy comparison of imagery from piece to piece or of the same hardware on different dates or locations. The DTI system uses a high resolution digital camera to capture a full 360° image of each of the following attributes:

- Pin connection threaded areas

- Pin connection nose surface

- Pin connection inner surface

- Box connection threaded areas

- Box end outer surface

Inspection anywhere, anytime

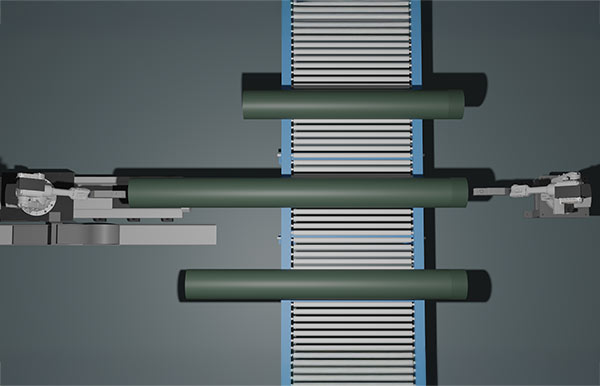

The mobile nature of the Tubular Solutions DTI system means you can take high quality inspection to wherever the job is. The flexibility of the 6-axis robot at the heart of the system brings unparalleled adaptability to getting a quality inspection of the hardware without the need to climb over and around a stack of pipes. The integrated control computer allows to user to quickly setup for inspection and review results immediately as they are captured.

A Permanent Record of Pipe Condition

Visual inspection reporting distills the pipe condition down to a simple pass/fail or a few short comments at best. The Tubular Solutions DTI system definitively documents the pipe condition in a digital format that is archived to allow review of the as-inspected condition today, tomorrow, or even after installation.

- Complete 360° image of all connector threads

- Automated defect detection

- Laser ID measurement

- Laser pipe length measurement

- Dimensional data validation

See Issues Before They Become Problems

The only thing worse than finding a damaged connector is installing one. The Tubular Solutions DTI system uses artificial intelligence to analyze the captured imagery of the pipe threads and automatically alert the user to potential defects. Each image is labeled with a degree scale indicating azimuth across the image and all identified defects are clearly marked for user investigation. Capturing the entire thread section in a single image allows for any and all found defects to be rapidly assessed and either cleared or rejected.

Save Data. Save Time. Save Tubulars.

Cloud-based storage Tubular Solutions utilizes a cloud-based data storage system that is exclusive to the DTI System. Everything we capture about every tubular we touch can be stored permanently and accessed easily. Here you can find all documents with information pertaining to each and every tubular in your inventory, including:

- MTR’s

- Laser and ID length

- Digital Images with time date and stamp

- Torque-Turn data Inspection reports

All data collected can be converted into PDF format, and an electronic report is generated for every client.

Everything You Want to Know About Every Tubular in Your Inventory.

With Tubular Solutions, experienced, highly-trained personnel capture accurate data. But the real value comes from knowing what to do with it, and the benefits are realized at every phase of your project…and beyond.

The Only Sensible Way to Address Your Tubular Needs.

The TTMS software we use has been custom-designed to parse your tubulars’ data in any way you need. One key feature of this system allows the client accessibility and tractability of material returning from rig site driving further efficiency gains. Data such as length, ID's, damages and repair history allow the material to be routed properly and alleviate the burden of a tally or ID measurement multiple times on the same joint.

Next Steps

Custom Solutions

We highly recommend partnering with us for all your tubular needs. But you may have some or most of those tasks already assigned. But for anything else, we are ready and eager to put together a package of services you still need to fulfill.

Put DTI to Work for You

Digital thread inspection is a game-changer, affecting a variety of critical tasks, and potentially saving time, money and manpower. So talk to us about putting it in action on your projects, and don't get left behind.